Chen, guan-jhih

As our circle of knowledge expands, so does the circumference of darkness surrounding it. - Albert Einstein

Tuesday, June 30, 2015

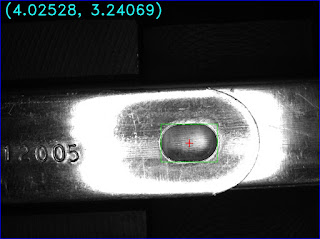

Thickness Measurement on friction Stays

One station of the friction stays automation is detecting the thickness and two gaps using CCD with the back light.

The algorithm using the binary cut technique with the edge filter is stable in easily ROI setting parameters.

Left Type:

Right Type:

Saturday, June 13, 2015

A gap length detector from the top view of multiple types

To detect the friction stays gap length, some locating and clustering methods are used with simple setting factors.

The effect is shown below:

Left three Types:

Right three Types:

Tuesday, June 02, 2015

A heavy scratching detector (AUTO ROI with spotlight)

Friday, January 30, 2015

Saturday, January 18, 2014

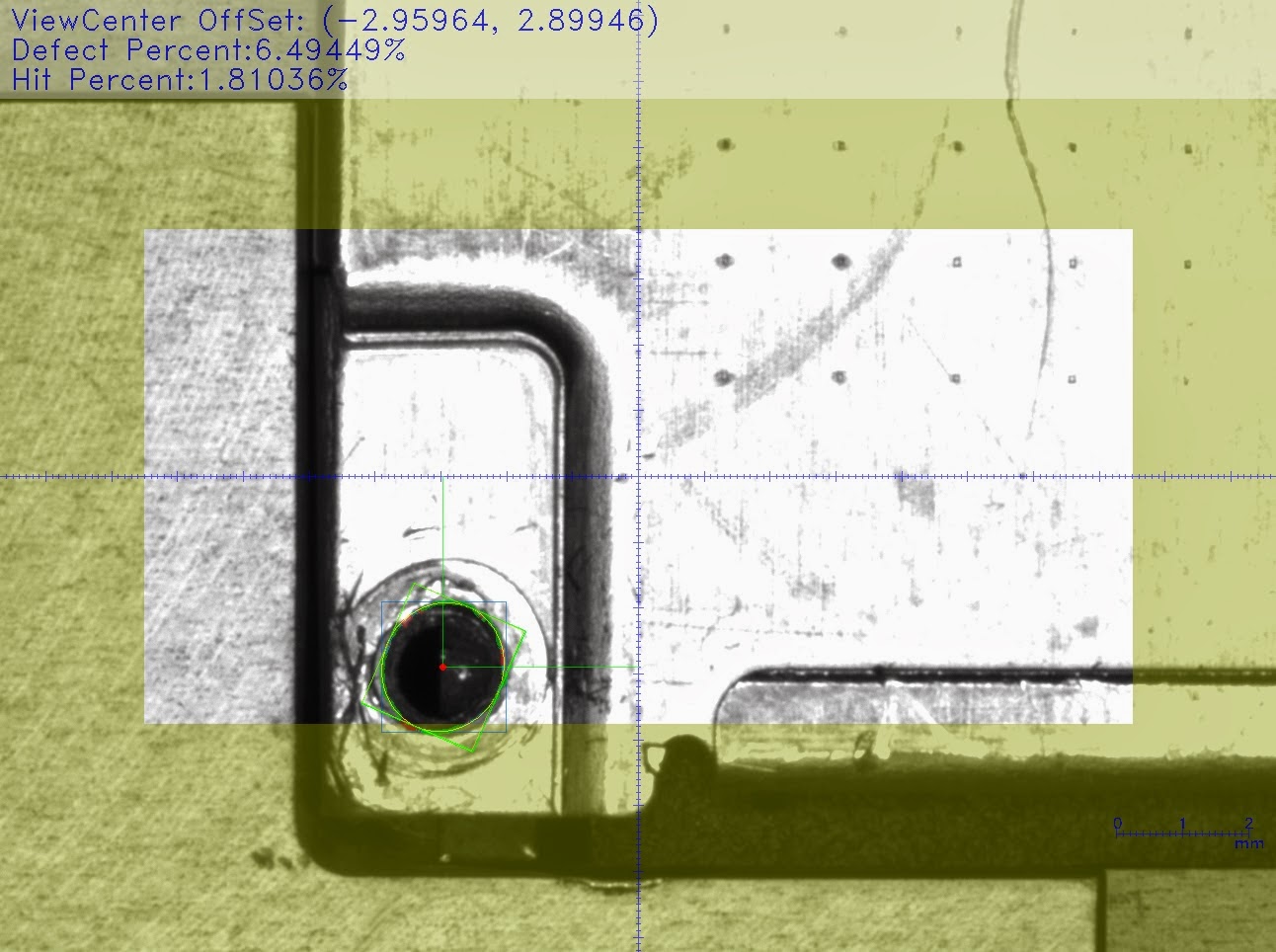

A hole detector

A rotary cylinder auto screw locker

I made the system software - a rotary cylinder auto screw locker with two air spanner and six-axis machining center (4 for air spanners, 1 for rotating the rotary cylinder and 1 for camera moving.)

The vision algorithm locates the position of screw holes, the system detects the height of the screw by touching the screws which monitoring the differences between the motor pulse and driver command pulse with the air spanner.

It's fun in monitoring the pulse difference in various velocity and loading though the progress is totally slow.

Subscribe to:

Posts (Atom)